Frequently asked questions

For Etching or Engraving into Mother Of Pearl Veneers, our recommended settings would be power 10 and speed 12– 1000PPI (=1000 Pulses Per Inch)

For laser cutting Mother Of Pearl material we use 60watt laser machine.

For our 0.3mm thick veneer sheet cutting: our recommended settings are Power 45 and Speed 12 – 1000PPI (=1000 Pulses Per Inch)

For our 0.3mm veneer sheet backed with Peel and Stick Material- our recommended settings are Power 90 Speed 12– 1000PPI (=1000 Pulses Per Inch)

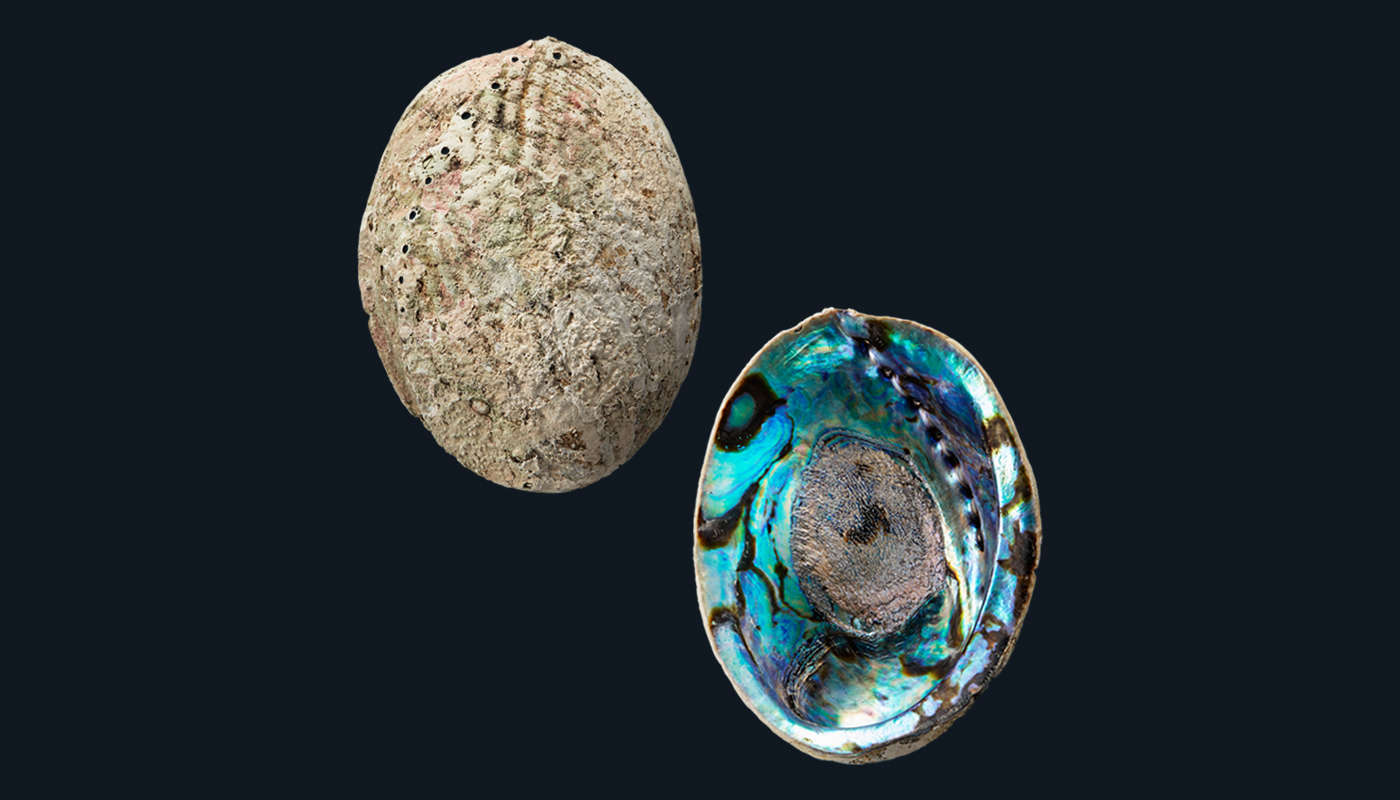

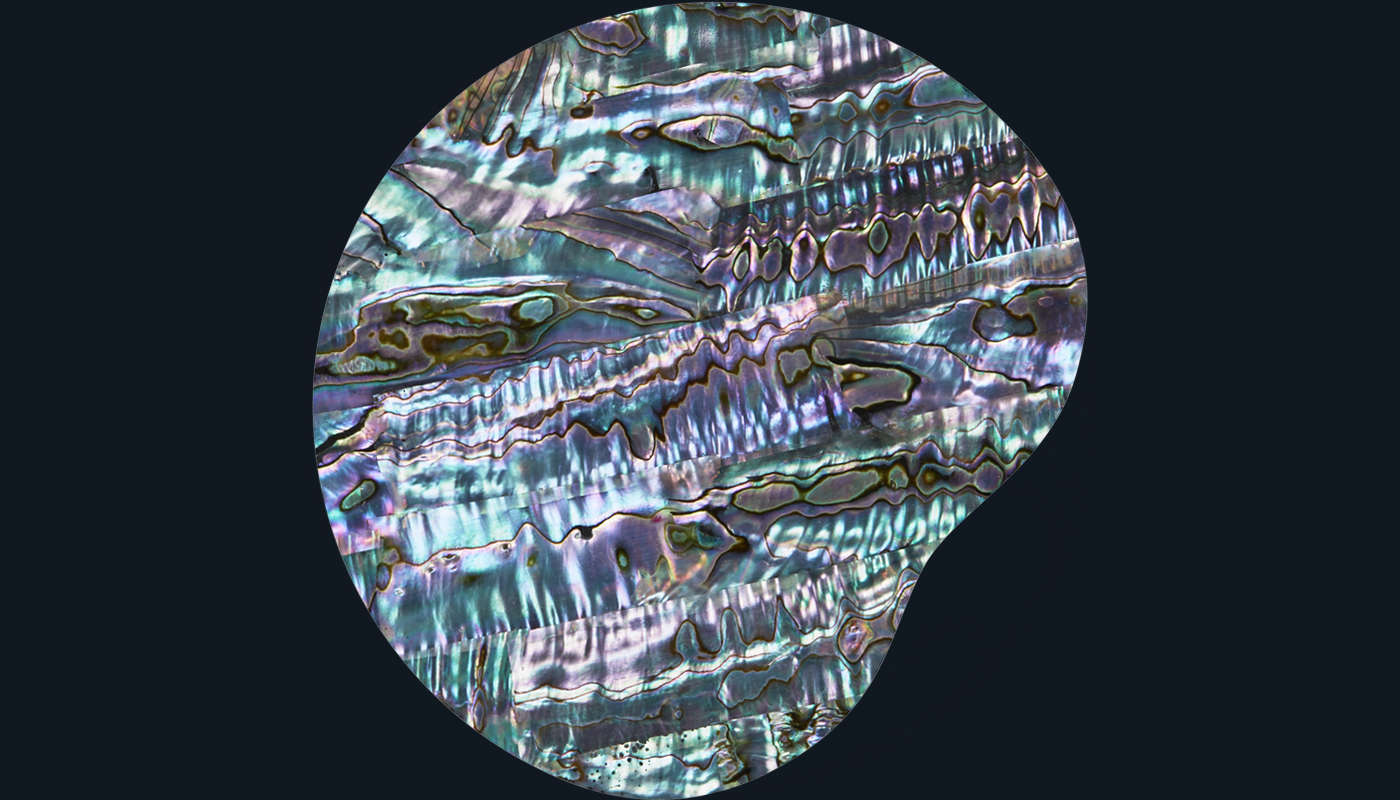

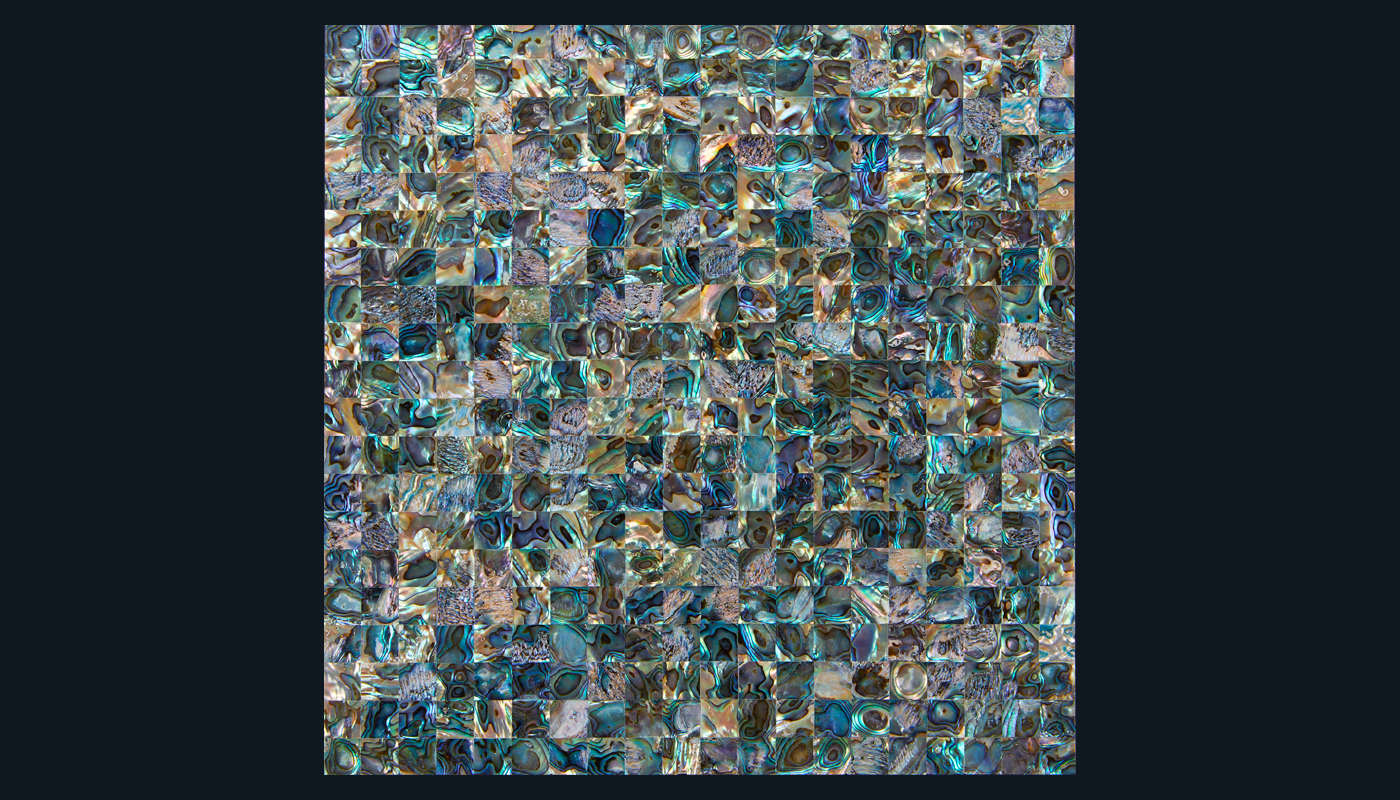

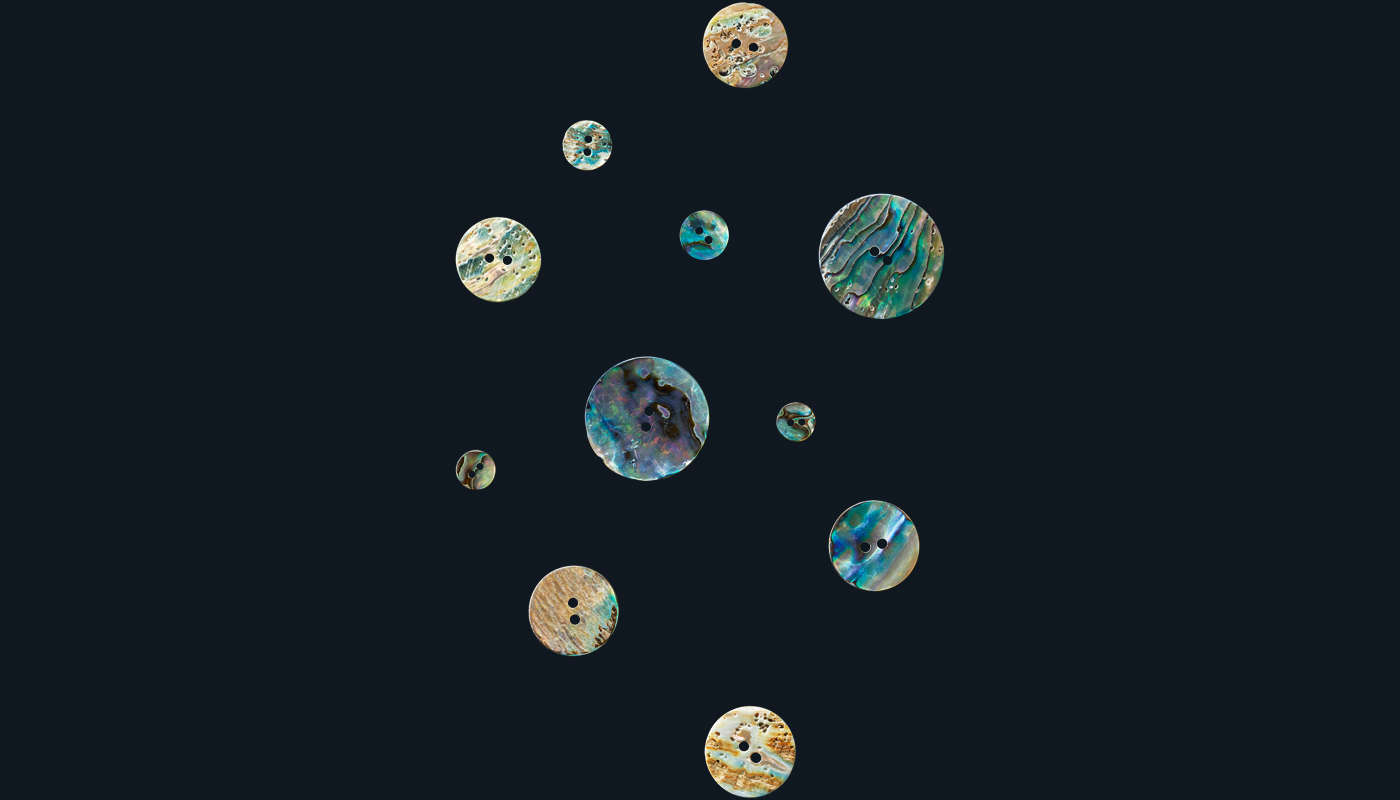

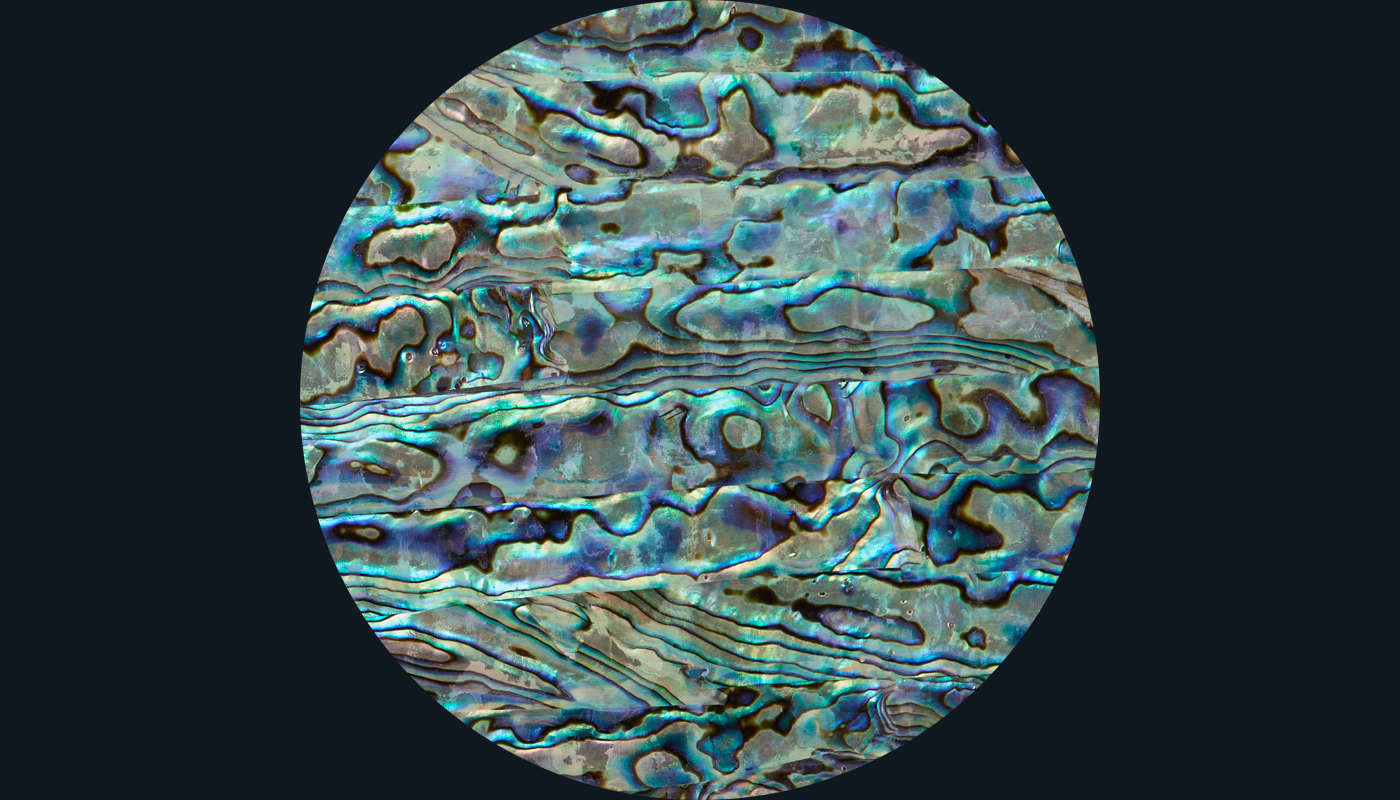

The black lines on the Pāua shell are called concholon , they are essentially nature's glue which bind the many layers of calcium carbonate which make up the shell. The blotchy concholon sometimes found on the inside of the shell is like a glue over run. They are always different as each shell grows differently and this is formed by nature after all. The concholon is very important not just as glue, but it also helps to give the shell that amazing blue-green colour, without it the colours would be more translucent looking.

Shell veneer is only 0.3mm thick, astonishing if you think it is made out of slices of real shell. For some designs we know that this is not enough. For those applications we are offering other products:

Shell veneer adhered to an acrylic backing to achieve a total thickness of 0.6mm which is perfect when using in conjunction with wood veneer which as standard is 0.6mm thick.

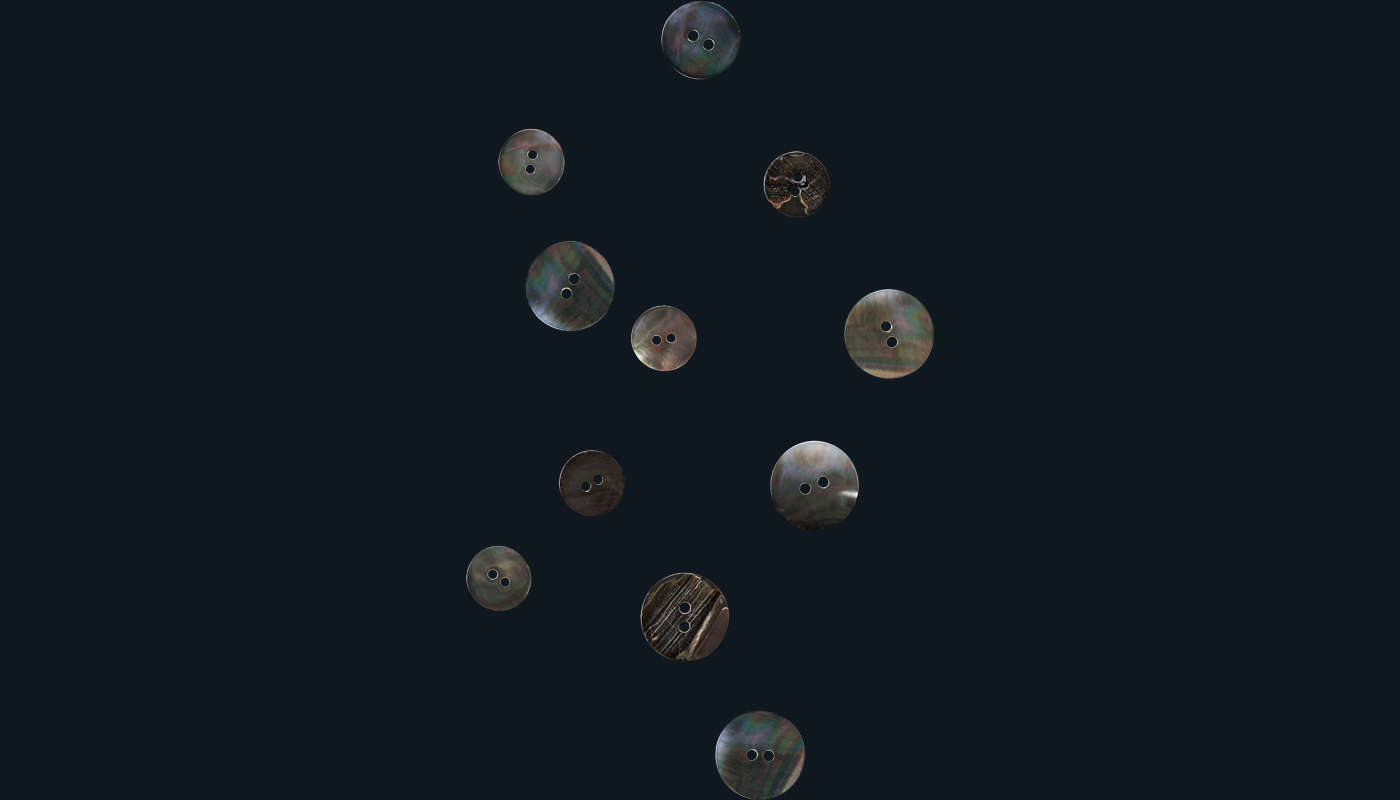

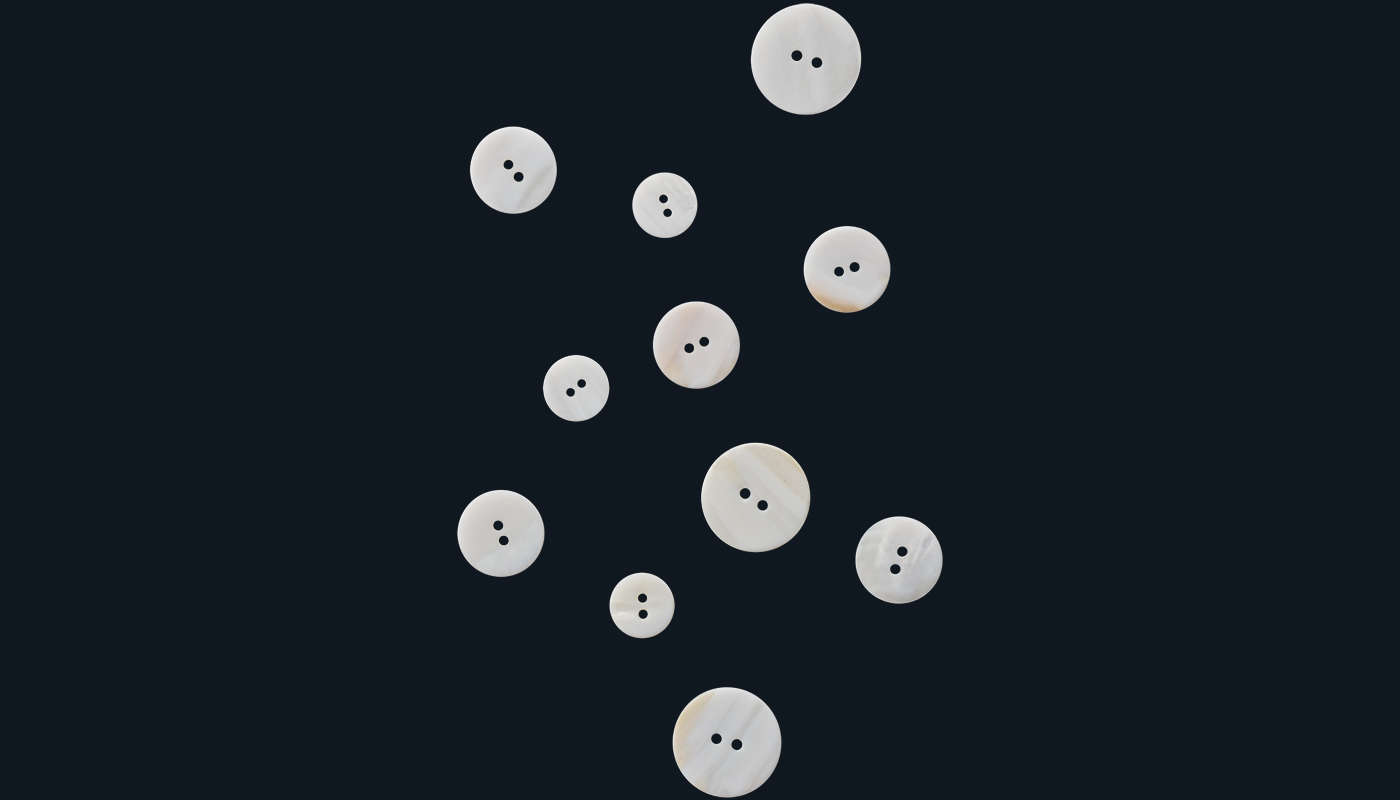

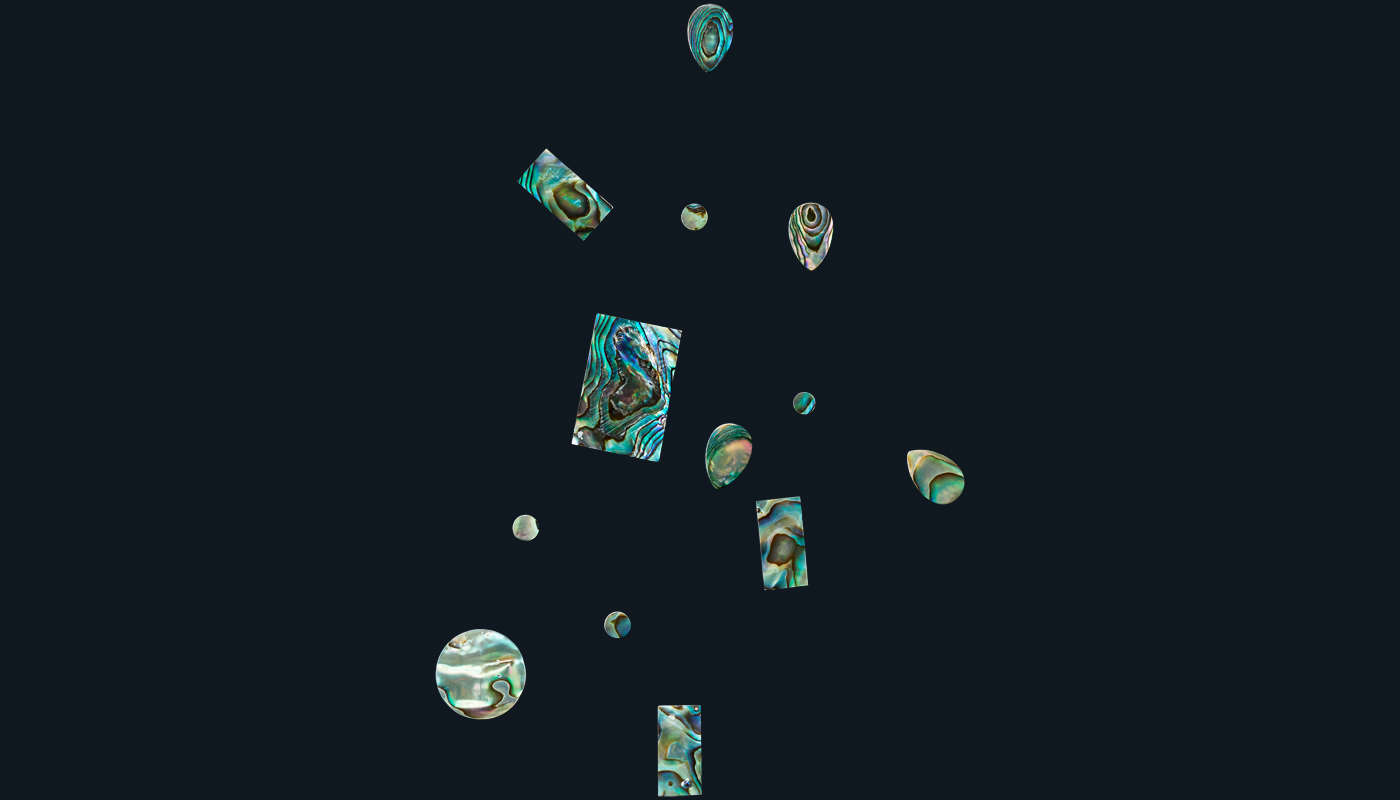

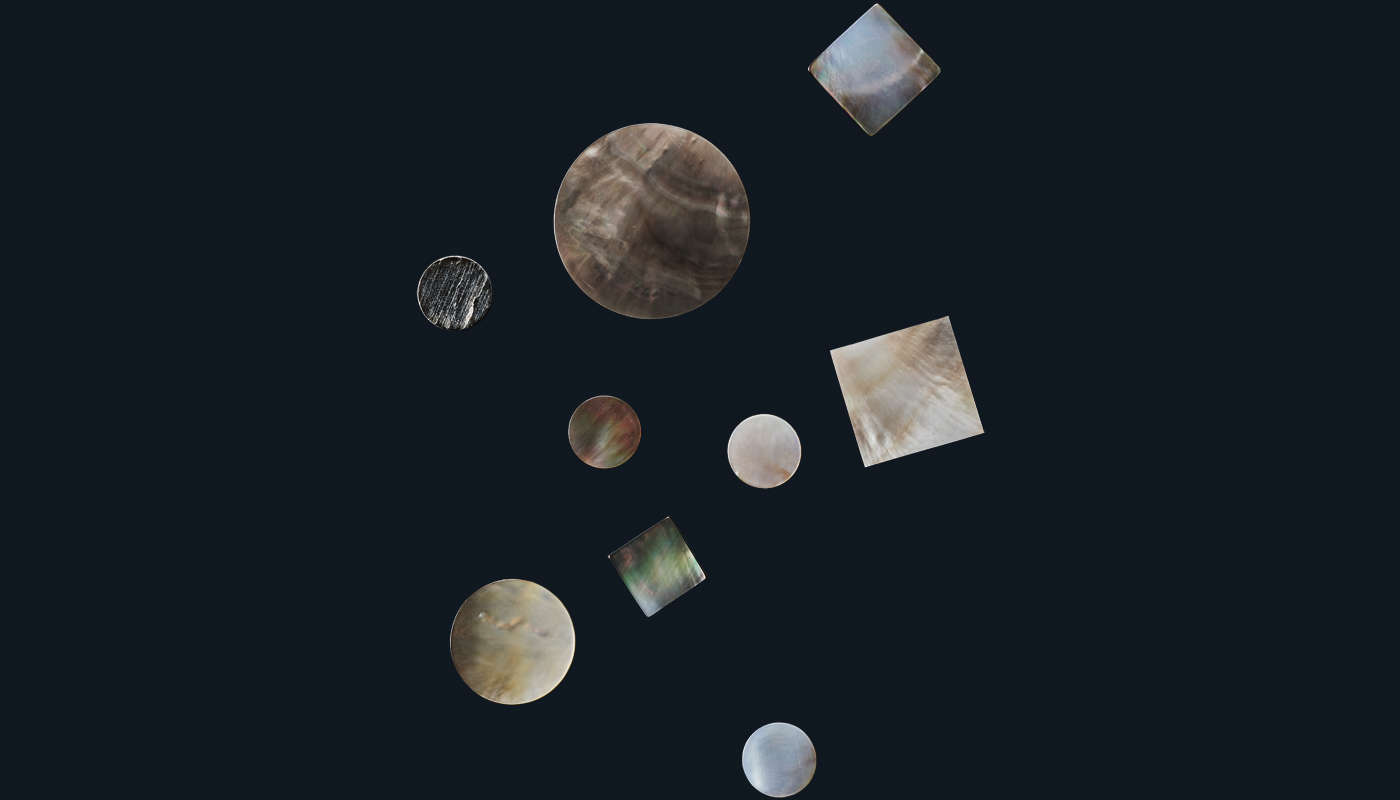

Solid shell blanks – Shell blanks come in different types of shell (White Mother of Pearl, Paua, Black Mother of Pearl, Freshwater etc.), and different shapes (round, oval rectangular etc.). These are different shapes cut out of the shell, so they have the natural curve of the shell. This limits the size and shape and also how they can be used.

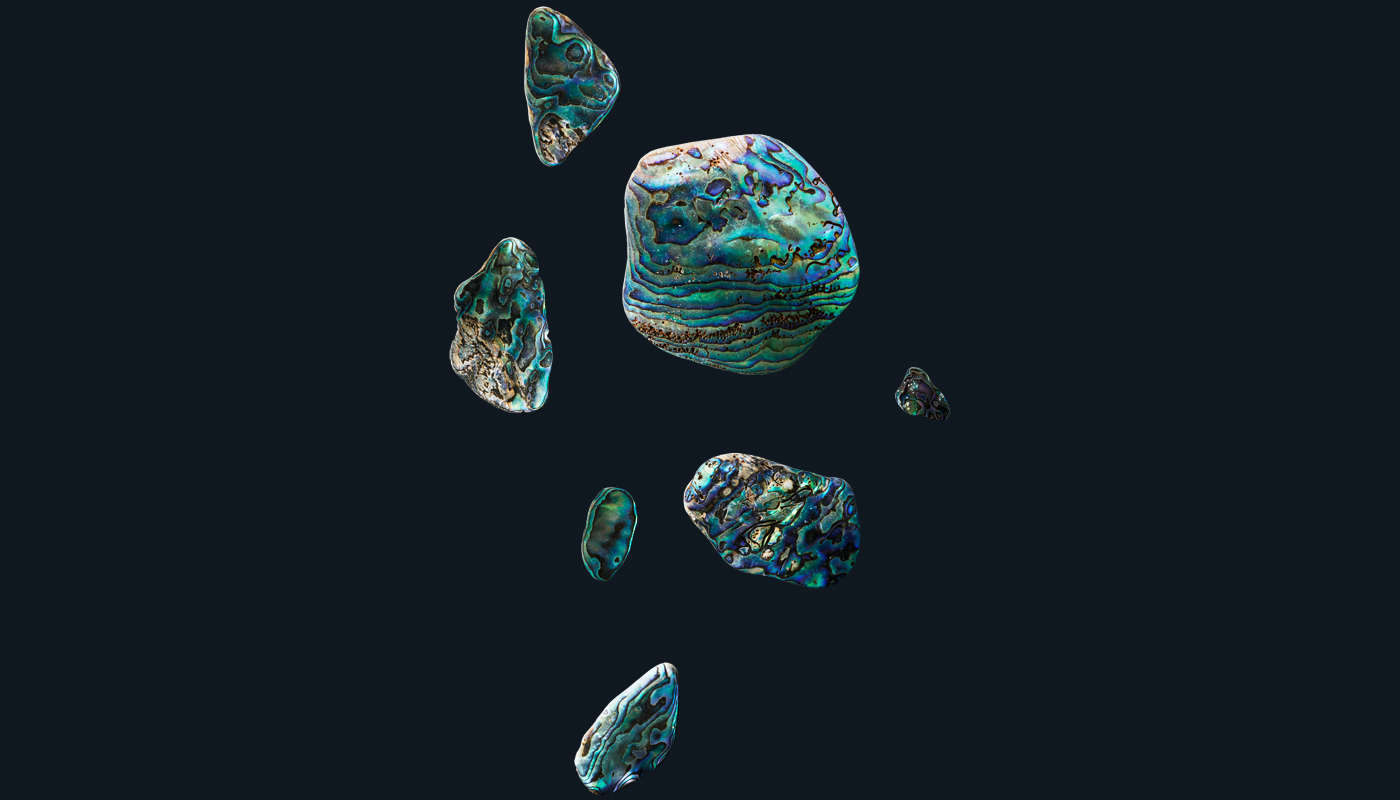

Composite – Composites are made out of several layers of shell veneers bonded together. We offer 3-ply composites in 1mm thickness, and 5-ply composites in 1.5mm thickness, either in New Zealand Abalone (paua) or Mexican Abalone. Composites are uncoated.

Shapes – We offer standard shapes cut out of composites. They are thicker than one layer of shell veneer, and they are flat. Ask us for a quote.

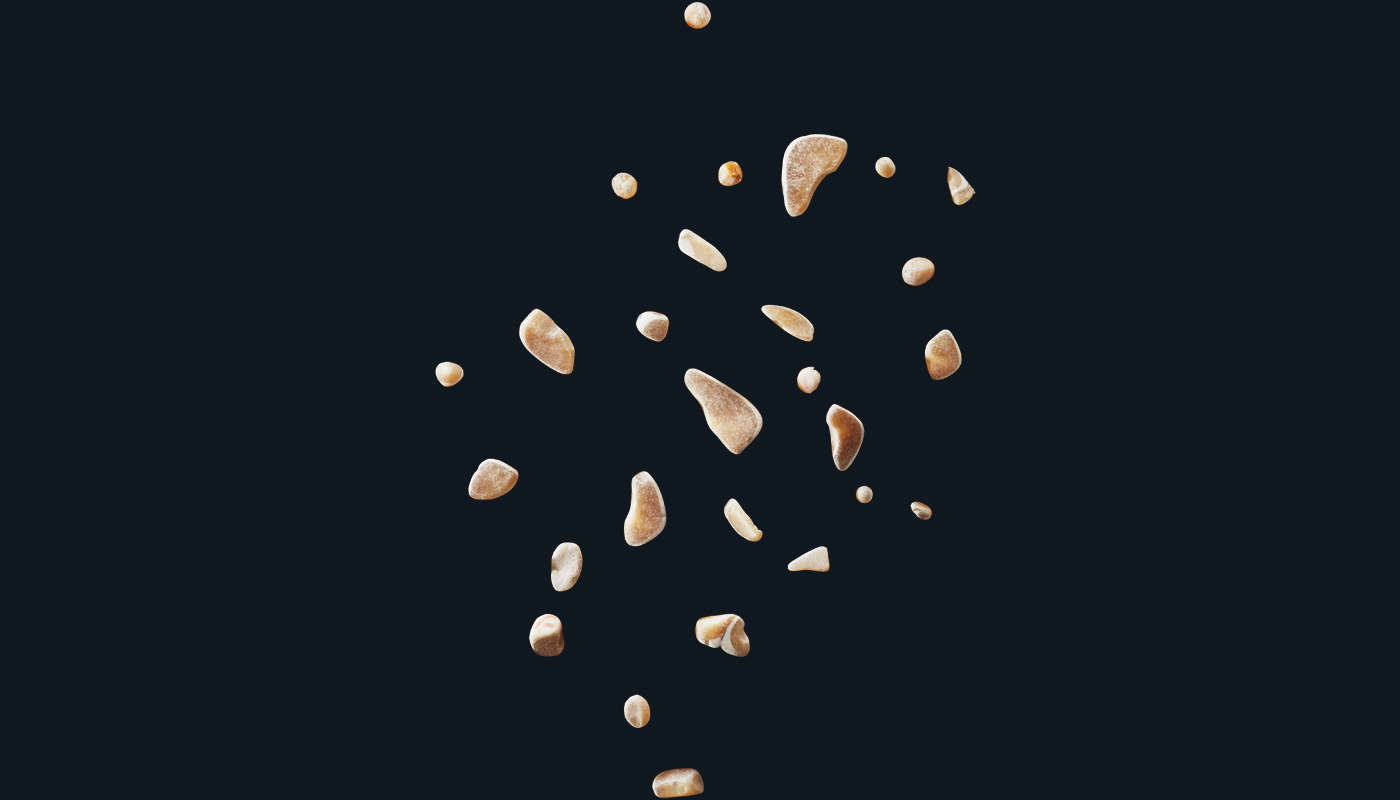

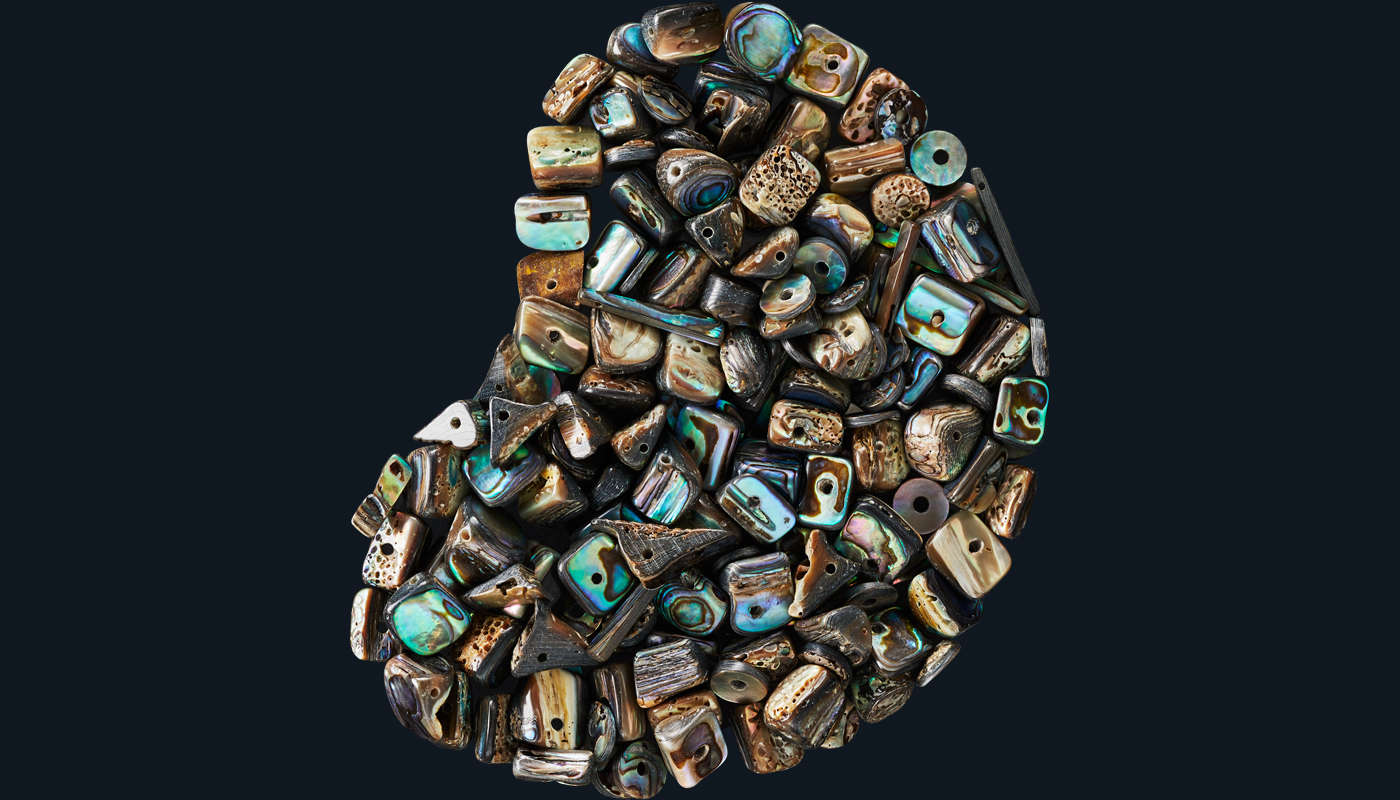

Tumbled Shell – Often the most individual solution is the use of our packs of tumbled shell. We have graded them into different sizes. You can cut and shape them to the perfect fit for your project. They are pieces of natural shell. Thicker than shell veneer, they are unlikely to be flat.

Lots of options for creativity!

A shell composite is made of several sheets of shell veneer glued together. It creates a thicker veneer in natural colour. We offer 3-ply composites in 1mm thickness, and 5-ply composites in 1.5mm thickness, either in New Zealand Abalone (paua) or Mexican Abalone. Composites are uncoated and perfect for inlay in projects where you need to sand the top layer.

Shells are beautifully made by nature. We are using language to describe what we see. Shell grading is never perfect, but it can guide us to describe a naturally made product.

Grade A is a clean shell with minimal disease. It has good colour, and no lumps.

Grade B is a shell that may have disease and lumps, may be discoloured or has some worm, or a combination of any of these.

Grade C is the same size but has more of the disease or discolouration.

Shell veneer can be applied to most flat surfaces, and – if cut into the right shape – even to some slightly curved surfaces. Before you start covering your instrument we recommend to have a chat to the guitar manufacturer. They will be better able to tell what effect it has on the sound quality instrument. We would recommend applying a thicker coating if the veneer would be in a place that would get scratched or suffer from wear and tear, such as a pick guard.

We work with a number of instrument makers around the world, who create their own shapes and designs from our shell veneers. We send custom designs from New Zealand to the rest of the world on a daily basis. If in doubt, please check with your local authorities if you are allowed to import shell products. We can lasercut to your requirements; please contact us for a quote.

We offer shell veneer as sheets in three different sizes, 230*130, 200*200 and 300*300. The standard sheets are painted at the back, to enhance the veneers' colours. We offer shell veneer with a commercial peel & stick backing(Commercial Double Sided Tape), that adheres to most surfaces like metal, glass, acrylic and wood. Shell veneer can also be glued with two-part epoxy.

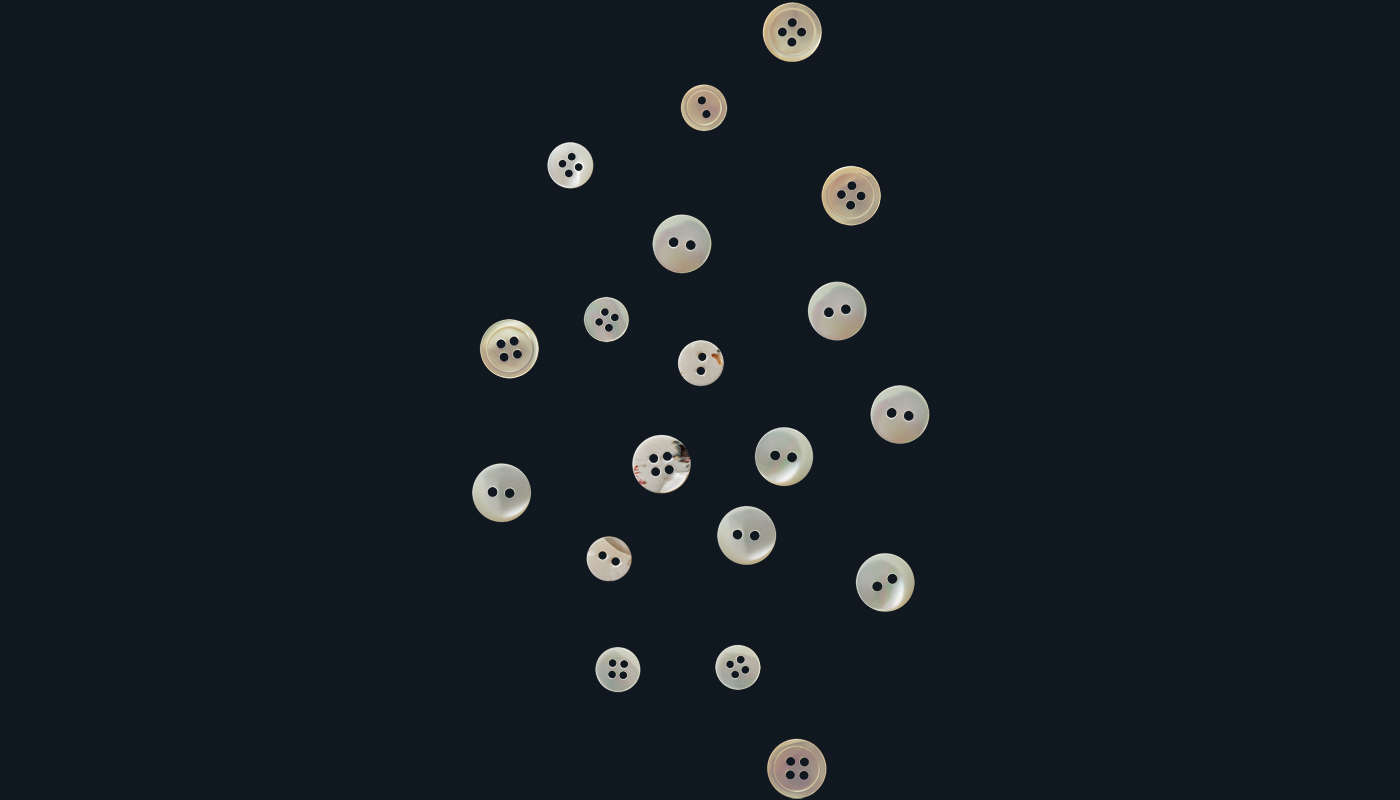

Describing the size of a button in millimetres is common. But millimetres where only defined in 1793. Around that time the measurement in ligne (L) for buttons was quite common, and has survived in some areas. These days, L is used in millinery (hatmaking), watchmaking and for buttons.

Here some measurements for reference:

10mm - 16L

11.25mm - 18L

12.50mm - 20L

15mm - 24L

17.5mm - 28L

In our catalogue you see the amazing colours we have developed for our coated shell veneers. These get applied with the coating of the shell veneers. Note when you sand the shell veneer that you are likely to sand through the coloured coating. For an application where the final product needs to be sanded we recommend using composite veneers.

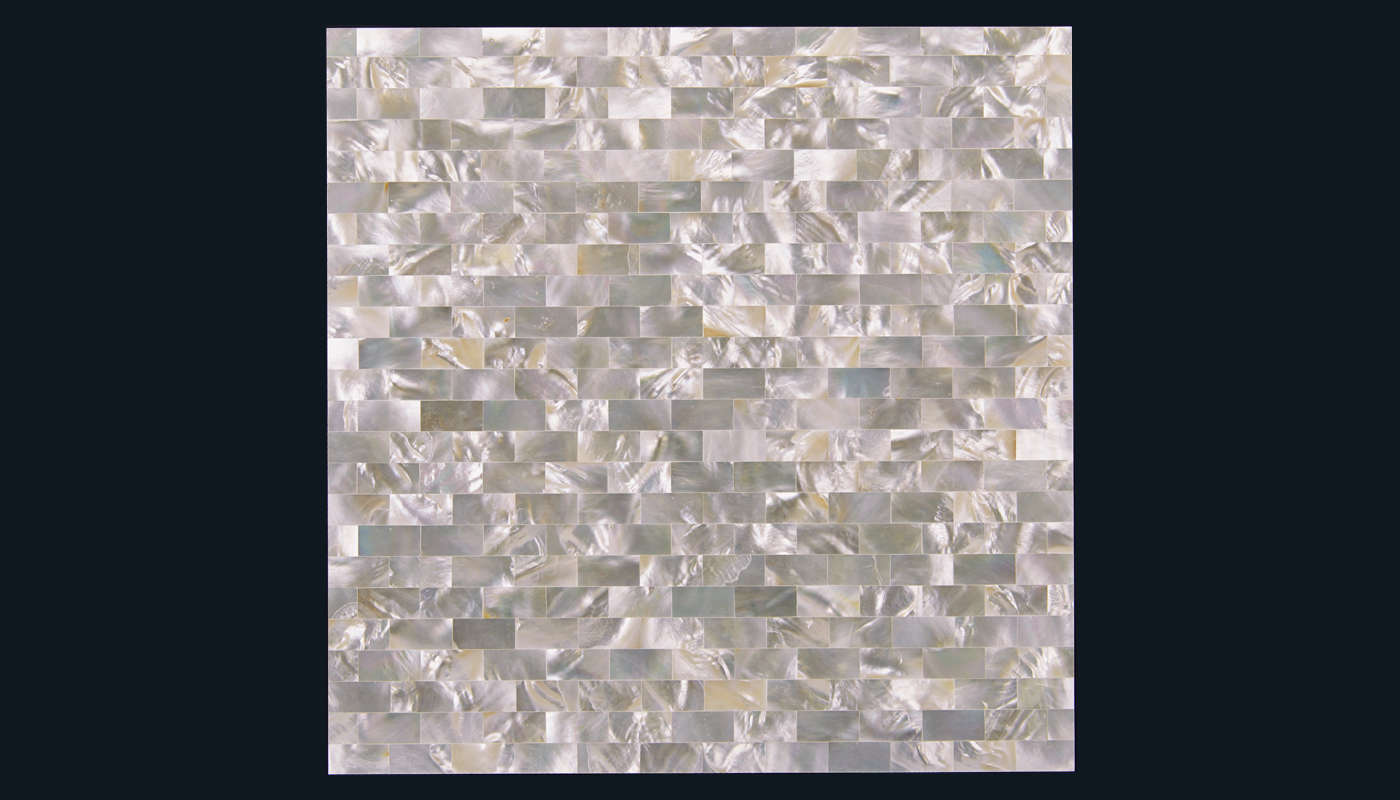

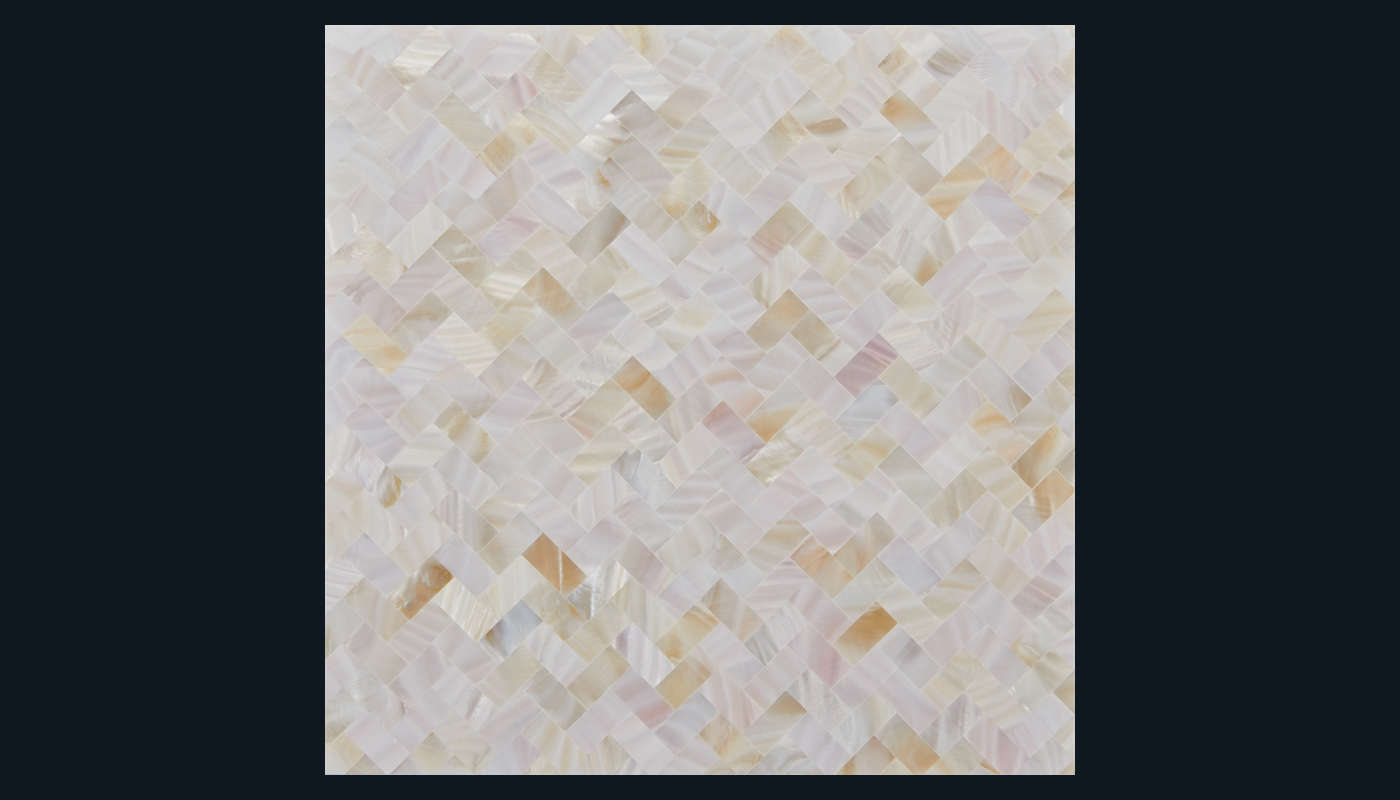

Natural Mosaic or Natural Strip describe how the feather-thin strips of shell veneer are arranged on the sheet: in a mosaic-type form or strip-like. Natural also describes that they have had a clear coat of laquer to protect the shell veneer; it enhances their natural colouring. No colour is added to the coating process.

Shell veneer is a fascinating product: Imagine a shell: a very hard, natural formation of calcium. Imagine it gets sliced up in 1cm wide strips - and then these strips get sliced into ever thinner slices, while still being 1cm wide. These feather-thin strips get bonded together, and then – we have shell veneer. The thickness of shell veneer is only 0.3mm. It displays all the characteristics of the shell it is made from: colours, ripples, it shimmers and shines. The advantage of shell veneer is in its flatness, and that it can be cut by hand into shapes.

We sell beads and component in many different types of shell: Paua, Black Mother of Pearl, Trochus, and Freshwater Mother of Pearl. Have a browse in our retail shop: there are hearts, dolphins, fans, circles and squares. And if you want to be even more creative: check out our tumbled shells from extra small to extra large - and create something great!

There are several ways of cutting shell veneer, anything from craft knife to laser cutter. It depends on the tools available, your experience with them and what effect you are trying to create.

A very efficient tool is a laser cutting machine. We use a CO2 cutter. It can cut extremely accurate and detailed designs, or a large number of small repetitive shapes. Luméa provide this service upon request. Drop us a line, and we will send you a quote.

Alternatively: Try a craft knife or scalpel and a metal ruler, or something similar that is the shape you require - we recommend testing a small piece first. Do this mainly for cutting straight lines. Use on a hard surface, press down firmly on the line or position you wish to cut. Drawing the knife gently across a few times times - just use gentle pressure -, scoring the shell deeper each time until it separates. Repeat several times with increasing pressure as you cut through the shell into the adhesive backing (if it has been applied). This should give the best result.

Scissors - Must be very good quality, very sharp with tight blades. Scissors can be used to cut curves. Using masking tape on the edges may minimise any fractures to the edges. We have found scissors generally cause minute cracking along the edge, which may not be acceptable to your project, depending on intended use.

You can also use is a high speed fine tooth blade, e.g. router or circular saw with diamond blade.

For all shell types, we use Urethane Acrylic Gloss Finish. This is a unique high performance two component finish coat with excellent resistance to abrasion, moisture, petroleum solvents and mineral and vegetable oils, alkalis and acids. UV stable.

On request for unique situations only: On New Zealand Abalone Natural we can use a UV cured acrylic gloss urethane.

Spray coated as 100% solids coating with excellent resistance to abrasion, moisture, petroleum solvents and mineral and vegetable oils, alkalis and acids. UV stable.

The minimum order requirement is your creativity. All our products are shipped around the world on a daily basis. If you are a returning customer please email us so we show you how to register your account for orders over US$300.

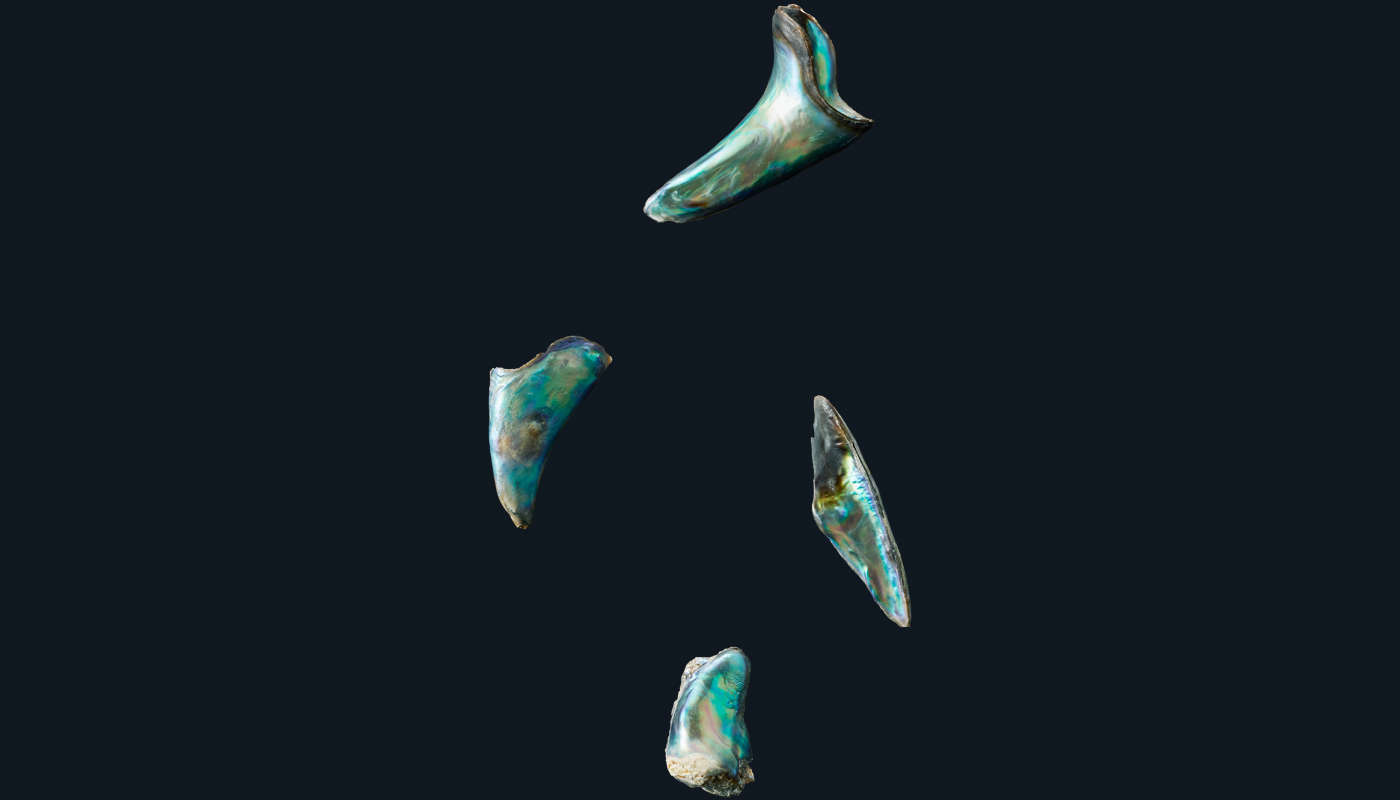

New Zealand Abalone (paua) is harvested under a quota management system. Commercial divers using a blunt metal tool, which doubles as a measuring device, loosen the paua from the rock. Each paua is recorded by the diver who is wearing a data logger, which tracks their location and how many paua are collected. The information collected is used by the Paua Industry Council to ensure the paua resource is managed sustainably.

The standard thickness is 0.3mm, however because this is a natural product the thickness may vary plus or minus 0.1 mm.

Our standard sizes are 130*230mm, 200*200mm and 300*300mm. We also offer smaller sizes with adhesive backing, in case you want to try out several different colours and how they behave in your particular project. We offer standard shapes, like strips, circles, ovals, rectangles and squares. Our experienced team offer to cut your custom designs on our state of the art laser cutter - ask us for a quote.

Technical support

Care and expertise are required when working with shell. Get the right answers and details about our products and applications. Read our technical specifications.

Tell us about your project...

Your project is unique, so we provide personalised advice before delivering worldwide from our studio in New Zealand.

Luméa products are made from natural shell with a variety of factors that affect form and function. If you can’t find the right product from within our range, then talk to us about our custom design service. We love to experiment and collaborate with our partners to create unique solutions.