Blue Abalone Shell Jewelry and Mother of Pearl Jewelry... A World of Its Own!

Shell Pieces, tumbled and polished by the ocean, have long drawn the attention of indigenous habitants and visitors alike. To this day, their unique colors, iridescent depth and unusual shapes designed by nature have been a trigger for creative minds.

From early currency coinage to highly sophisticated applications in modern jewelry, Abalone and Mother of Pearl's polished pieces have rivalled in beauty with highly rated mineral gems.

33 years ago, Ocean Shell Ltd was a commodity broker selling only Pāua shell to the Asian Markets: jewelry factories were the main buyers. Along the way the company started taking the Australian White Mother of Pearl and other seashells to Swiss Luxury Watch Dial Makers and European fine Jewelers.

So, it's no surprise to see the passionate Ocean Shell family still attending the prestigious Tuscon-Arizona- Gem Show, held in early February each year. Flying the New Zealand Flag is part of the mission, but the early history of New Zealand Abalone Paua and Mother of Pearl as Jewelry components will be celebrated once again.

Today, let's look at the various types of shell components and how they carved their own special space in the spheres of Jewelry.

Raw Ocean Gems.

New Zealand Abalone Paua Pieces

Early tribal jewelry celebrated the beauty of shell pieces directly from the beach to the hooks of earrings and the strings of necklaces. Today the tradition lives on with silver sterling jewelers and the likes. Here, very little treatment is applied except for some polishing to enhance the shine and bring out natural colors. The original shape is kept as made by the ocean.

Today, the artificial process of tumbling shell pieces simply replicates the work of the ocean. Ask Bruce Shields, originator of Ocean Shell Ltd, to reveal his secret recipes for the attractive shine and vivid colors of his satin shell pieces made for jewelers, and you should expect an evasive answer with a smile... Artificial tumbling also ensures that every part of the shell is used, including the lip, or shell rim.

Adding other materials for special texture is also used as a simple way to enhance natural, satin shell fragments. Here some ideas from a French Jeweler, Lionnel Aubert

Fine Jewelers look for a more sophisticated shape and a particular shine. More expensive shaping tools are required, and a high level of expertise in choosing and shaping gems. For this purpose, only some rare hand picked, 3 dimensional pieces in every few hundred tumbled shell fragments will be selected. The resulting creations rival with the finest jewelry pieces using mineral gems. Here, some pieces from Geoff Taylor and Julie Pijfers.

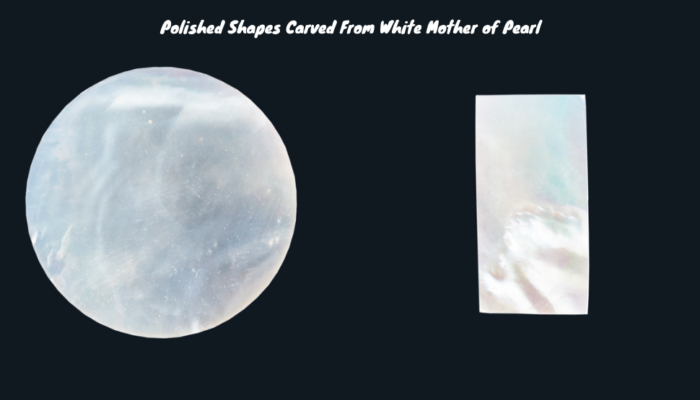

Carving From The Precious and Pure White Mother of Pearl

The tumbled shell pieces would be more difficult to produce with the majestic White Pearl Oyster, because it is hard to crush. Also, its high value means that carving blanks from the shell is a more viable, less wasteful option.

Polished Shell Blanks from White Mother of Pearl are the most common component in Jewelry pieces capturing the pure white iridescence in the thicker part of the shell. Naturally, it is some of the most expensive "Fashion Jewelry" featuring shell blanks.

By far the most glamorous use of White Mother of Pearl shell blanks is by prestigious luxury dial watch makers. Perfection is the norm here, with over 50% reject from large numbers of polished shell blanks, that would look spotless to the uneducated eye. One of the examples below also feature polished abalone (Paua) shell blanks.

Black Mother of Pearl and Pink Mother of Pearl (Pink Mussel)

Back to less precious species also used as ocean tumbled shell pieces: the French Polynesian black pearl oyster and the Mississippi pink mussels are a great source of alternative color tones in satin tumbled shell pieces for jewelry. Pink Mother of Pearl is a favorite for Indian Jewelers.

Carved and Polished shell blanks for Pink and Black Mother of Pearls are, once again, a more specialized creation demanding fine Jewelers' expertise, and fine tools!

Shell Veneers Bring Great Innovation and Versatile Use.

"Fashion Jewelry" has learned to capture the 3 dimensional depth of reflections displayed in a 0.3mm thick shell veneer sheet. Those "Laminate" Sheets have many advantages: being flat and thin, they can be cut into pre-designed shapes by laser or craft knife, applied to a flat substrate like wood, silver or gold plated metal. Importantly, they also provide a more affordable price point, with shapes that would not be achievable by carving and polishing.

The use of veneers means a good choice of tints and patterns featuring various shell species, all at a very accessible price. Black Mother of Pearl and White Mother Of Pearl Veneers are shown here.

More innovations from the Fashion Jewelry Industry: restoring the 3 dimensional look of carved and polished shell gems, using resin doming on shell veneer. The range of tints available is as wide as allowed by shell veneer designs, and the price range is an attractive option for the more casual wear.

When metal casing is possible, more freedom is allowed for customized shapes, laser cut from veneer sheets. Resin casting provides more depth to the shell veneer and a great alternative to carved and polished shell blanks. Once again, many of these intricate shapes would not be achievable when carving directly from the shell, and if they were, the price would be too high.

This technique is also used for some Pool Cues Inlay Pieces, where resin casting can be fine sanded flush with the convex shape of the cues.

Jewelry is right at the origins of human fascination for seashells, whether harvested live or collected on the beach. Today, jewelry continues to be at the forefront of innovation for the use of shell components in other industries.

Tell us about your project...

Your project is unique, so we provide personalised advice before delivering worldwide from our studio in New Zealand.

Luméa products are made from natural shell with a variety of factors that affect form and function. If you can’t find the right product from within our range, then talk to us about our custom design service. We love to experiment and collaborate with our partners to create unique solutions.