5 Unique Types of Mother of Pearl Sheets and Their Purpose.

By far the most common Mother of Pearl Sheets available to creative users on the wider market are the "gloss coated" version. The majority of Suppliers are also restricted to the 240mm X 140mm sheet size (9.44" X 5.51").

Yet, even our experienced clients sometimes surprise us by trialing a different type of sheet from their usual choice, in their search for new possibilities or problem solving.

Depending on your desired outcome and the requirements of your clients, some shell veneer types may be more appropriate than others. You will find below a simple guide outlining the advantages and attributes of each . This may even inspire you to some new product development!

1. Uncoated Shell Veneer Sheets

This the plain version, simply the raw veneer sheet, straight off the press. The thickness is around 0.2mm and

Practical Advantages:

It allows the manufacturer, artisan or artist to do their own final coating once the veneer has been inlaid. If the top side of the veneer is flush with the wood surface (or other support materials used), then the final coat will be seamless.

The uncoated sheet can be lightly sanded, when a perfect flush finish is required for the inlay after final coating.

Sizes: unlike most suppliers, the Lumea sheets are not limited to one size, choose from the following:

- 240mm X 140mm sheet size (9.44" X 5.51").

- 200mm X 200mm sheet size (7.87" X 7.87").

- 300mm X 300mm sheet size (11.80" X 11.80").

The final coating will always bond better with the raw shell surface in the long run.

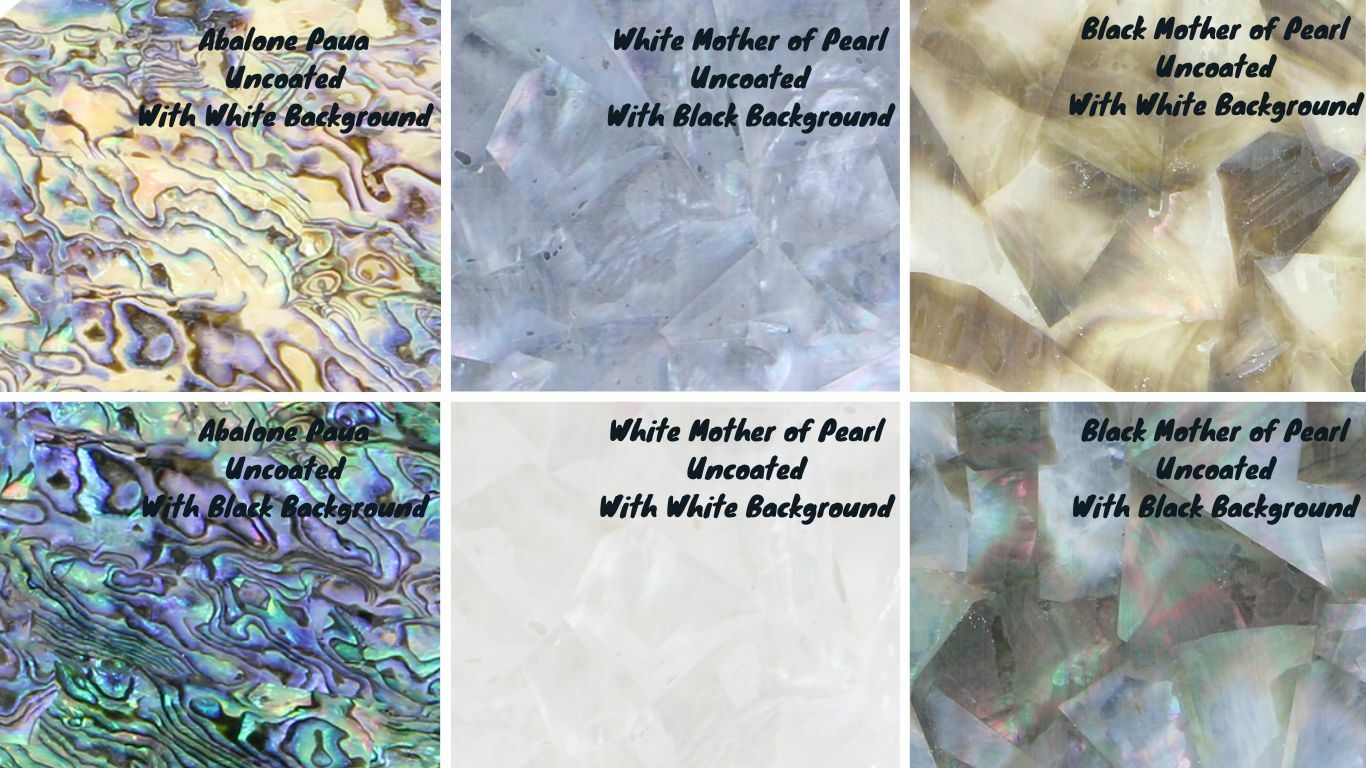

Uncoated sheets have a certain amount of transparency, which means your options are open. You can paint the back of the sheet to bring out some of the iridescent effects in the shell, or you can choose to let the colour of the substrate, most commonly wood, come across.

Uncoated white Mother of Pearl Veneers celebrate the iridescent whites, while darker colours are featured in the Black Mother of Pearl Sheets. Natural turquoise, blues and greens are displayed in the uncoated natural NZ Abalone Paua Sheets.

The Downside?

Only the natural colours are available in the uncoated shell veneers. This is because artificial colours in our range can only be added with the coating.

Some Caution Required:

- Because uncoated sheets have no back paint or coating to act as a protection, they can be a little more fragile, especially on the edges.

- With this in mind, it is recommended to cut the uncoated veneer with laser, for a clean cutting line.

- Where does the uncoated veneer sheet work best?

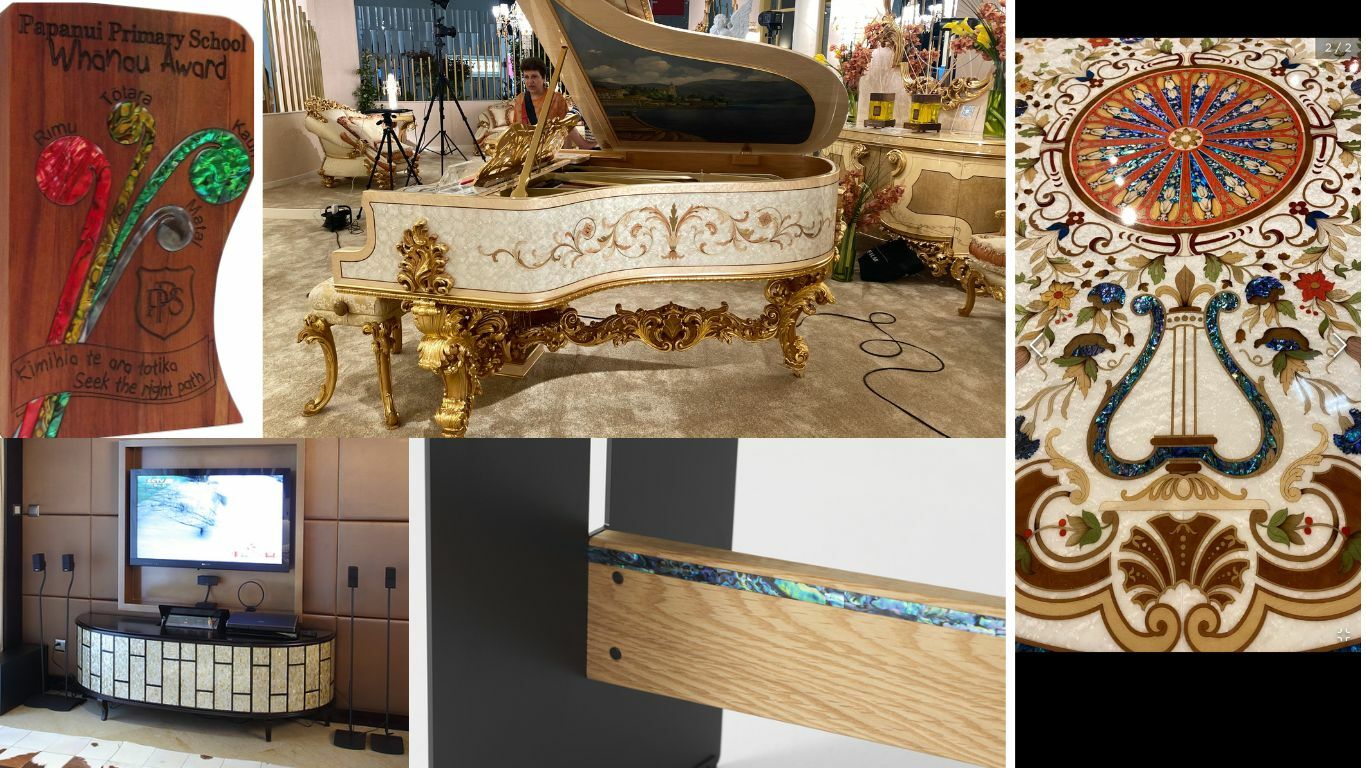

- In furniture inlay and interior decor, when the final coating must be absolutely, seamlessly perfect.

- In specialist manufacturing, where resin doming is applied, e.g. fishing lures and fashion Jewelry.

- Also perfect when you prefer the subtlety of natural colours, including the tones of natural wood, being visible by transparency through the veneer.

2. Composite Mother of Pearl Sheets

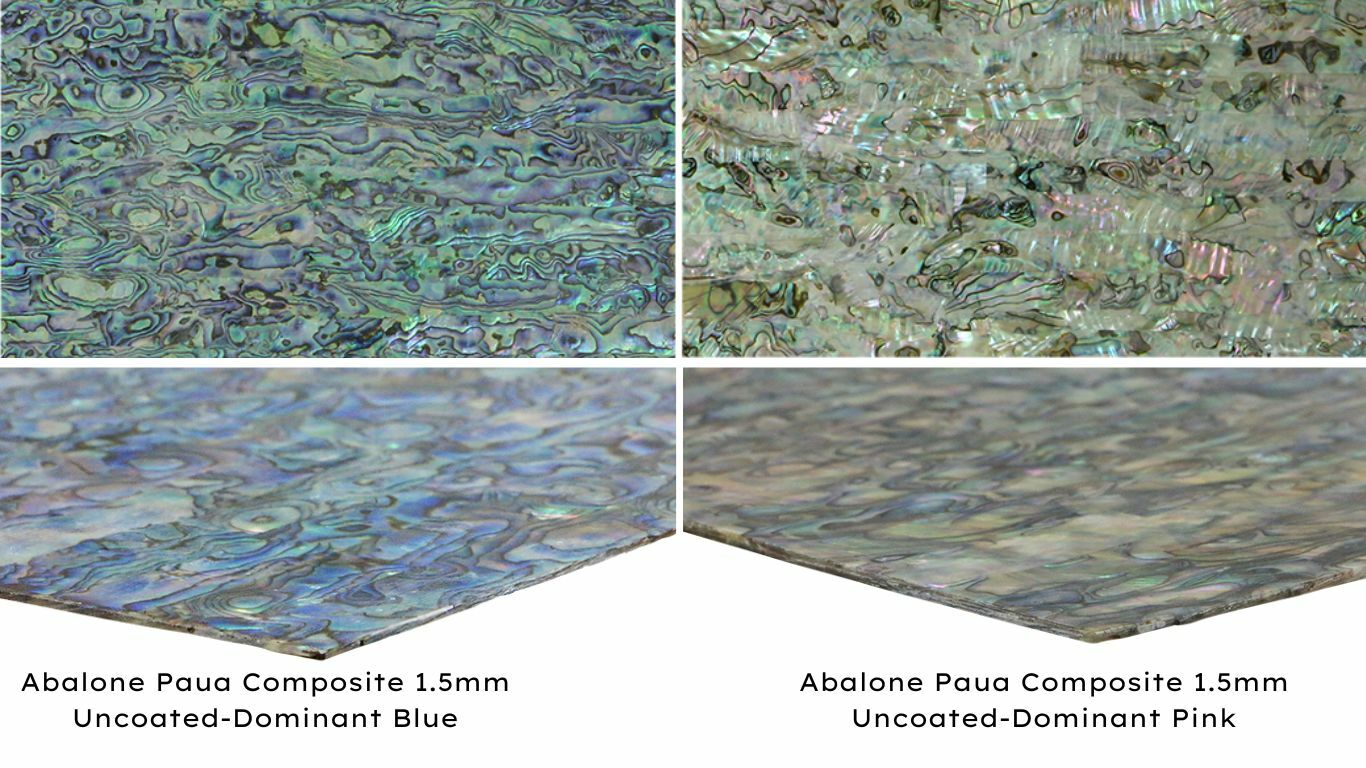

Composite sheets are the closest material to solid shell blanks, with the advantage of being perfectly flat and much larger than any Shell Blanks: 240mm X 140mm (9.44" X 5.51"). Also referred to as panels, they are made by bonding 3 or 5 uncoated Mother of Pearl sheets together, reaching 1mm or 1.5mm in thickness.

What problems does it solve?

- When seeking a smooth and flush surface, the composite sheet can be sanded once inlaid, without the risk of sanding through the sheet. This is mostly required in furniture and guitar inlay. Then the final coating can be seamless too.

- When working with curved surfaces, the ability to sand the composite for a flush finish is the main advantage, thanks to the 1.5mm thickness.

- For Jewelry and craft creations where a reasonably large shell piece is needed, but without the natural curve of a shell, the composite sheets are the only option.

- With 3 to 5 shell veneer sheets involved, transparency is no longer an issue, so the laser cut pieces can be inlaid directly in wood or any other material.

- By choosing the sheets for their dominant colours, you can emphasize the blues or the pinks in Paua shell sheets.

The Challenges?

- Just like the uncoated Mother of Pearl sheets, composites only exist in the natural shell colours.

- The cost of 3 to 5 shell veneer sheets bonded together can be a factor.

- Laser cutting, a scroll saw, or a jeweler's saw are the only reliable ways to cut the shell composite sheets.

3. Flexible Uncoated Shell Veneer Sheets

Greater flexibility is often crucially required when applied to a sharply bent or curved surface, or even a cylinder.

The flexible veneer sheets are made by intricately fracturing the "shell feathers" in an uncoated sheet that has been applied to an adhesive backing. The resulting micro fractures are hardly visible and iridescence in the shell remains intact.

What problems does it solve?

- Once a final coat is applied, flexible veneers provide a very similar look to a gloss coated veneer, but on curved surfaces.

- Flexible shell veneer sheets have largely widened the possible applications of Mother of Pearl Sheet. This includes their use combined with fabrics, in fashion and interior design.

- Pool cues, pens, fishing rods, fishing lures and furniture manufacturers, as well as interior decorators have all benefited from this highly versatile product, still made of genuine shell slices, only 0.1mm thick!

- Flexible veneers are thinner than the coated sheets, and very easy to cut with a craft knife or laser machine.

Any downside?

- As an uncoated sheet, flexible shell veneer only exists in the natural shell colours. In the case of pens, fishing rods and fishing lures, the final coat or the resin casting offers the opportunity to add a tint of your choice.

- They are only produced in the 240mm X 140mm (9.44" X 5.51"), simply because most applications are for small surfaces.

4. Gloss Coated Shell Veneer Sheets

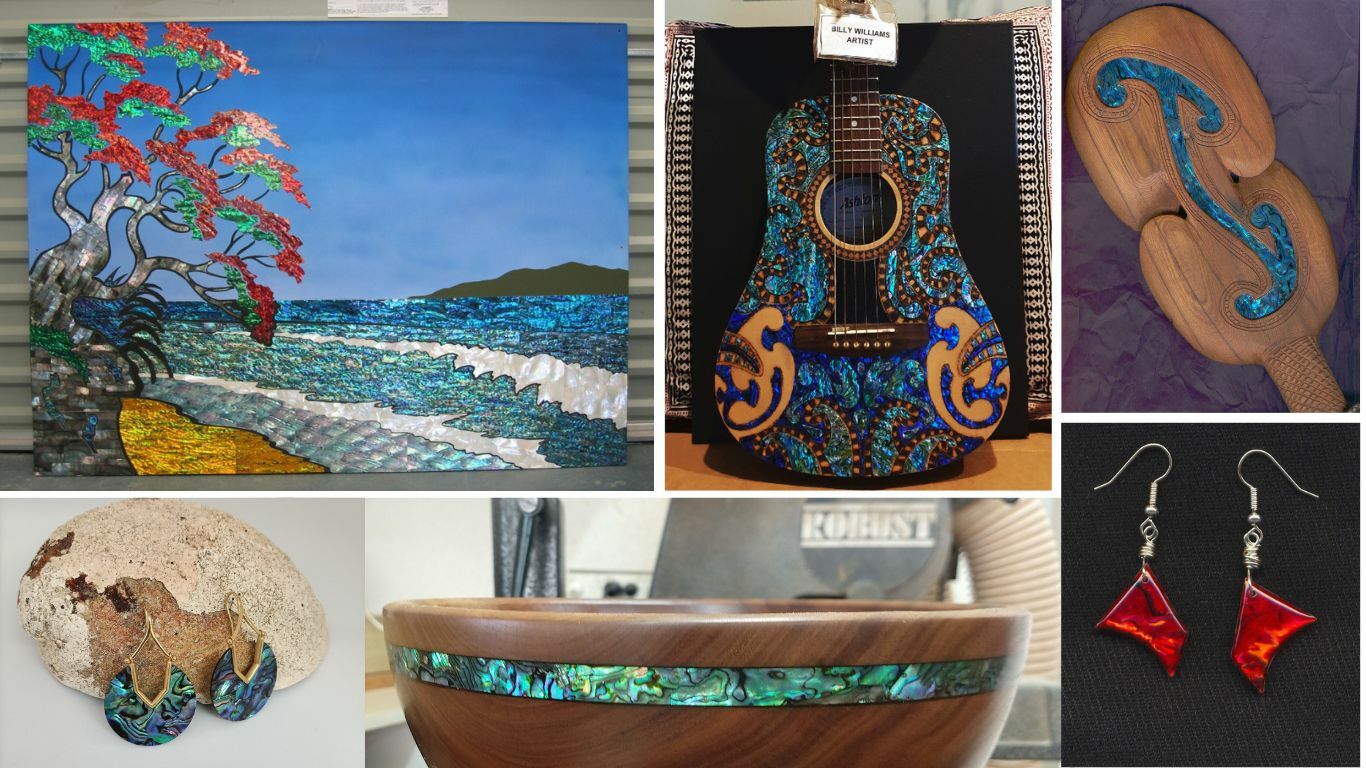

As the "go to" solution for many of our clients, gloss Coated Mother of Pearl Sheets are easy to use and suit a large range of applications. You will find gloss coated Mother or Pearl Sheets and Abalone Sheets in many creations from furniture inlay, trophies, pocket knives, to fashion jewelry and a large variety of craft creations.

Advantages to Designers and Makers:

The gloss coating is the most effective enhancement for the deep reflections and iridescence in the shell.

Sizes: here again, Lumea sheets exist in larger sizes seldom available on the sheet market.

- 240mm X 140mm sheet size (9.44" X 5.51").

- 200mm X 200mm sheet size (7.87" X 7.87").

- 300mm X 300mm sheet size (11.80" X 11.80").

Thanks to adding tints to the coating, 38 different patterns and designs make up our high quality range of Shell Veneer Sheets.

A layer of paint at the back of the sheet is used to avoid transparency and bring out the vibrancy of natural shell colours. Black paint is used for most of the Abalone Paua sheets, and white paint for the White Mother of Pearl Sheets. In some cases, the back paint matches the tint in the gloss coating e.g. purples, pinks and reds.

The back paint and the gloss coating provide protection for the integrity of the sheet, making Craft Knife cutting and laser cutting a lot easier.

Although not as flexible and versatile as our flexible veneers for curved surfaces, gloss coated veneers can be successfully flexed with the use of a heat gun.

The challenges?

- If your choice is to favor the subtlety of a a natural "look and feel", the vibrancy of gloss coasted veneers may not be at the top of your list.

- However, you may still find what you want in the natural gloss coated sheets, where no artificial tint is added.

- The thickness of gloss coated sheets can vary between 0.25mm and 0.4mm, depending on the shell species and manufacturer's choice. Check with our Mother of Pearl sheet experts to learn what best suits your project.

5. Matt Coated Shell Veneer Sheets

The matt finish has the advantage of limiting shiny reflections on the veneer, when exposed to intense lighting. It is quite a subtle difference: the vibrancy of the shell is equally enhanced by the coating, and all the technical attributes of this product are identical to those sited for the gloss coated sheets.

Matt coating versus glossy is a matter of taste: overall, more than 80% of our customers choose gloss coated.

Important Quality Considerations For All Users

Not all Mother Of Pearl Sheets are created equal. The quality of the product varies greatly, depending on the suppliers. For peace of mind when buying online, it is worth buying one sheet as a sample, unless you have already dealt with the same supplier. Here is a list of Quality indicators.

For New Zealand Abalone Paua Sheets:

- A good mix of vivid blues, purples and greens when choosing natural paua. This is not so crucial when buying a tinted sheets.

- Clusters of pin holes or blank circles can indicate a diseased or "wormy" shell, that affects the quality of the sheet.

- Consistent density in the "Black contour lines" that separate the shell layers.

- Reasonably seamless patterns between the shell pieces or "Feathers" in any one sheet.

For White Mother of Pearl sheets:

- The lack of shine or iridescence in any part of the sheet indicates the presence of "Dead Shell", to be avoided.

- Pin holes or little blank circles also indicate diseased or wormy shell.

- Traces of dirt indicate a lack of care when arranging the shell feathers into patterns.

- The size of the shell feathers must be consistent throughout the sheet.

When purchasing any Mother of Pearl Sheets from the Lumea brand, the quality is checked by our shell veneer experts before sending.

Tell us about your project...

Your project is unique, so we provide personalised advice before delivering worldwide from our studio in New Zealand.

Luméa products are made from natural shell with a variety of factors that affect form and function. If you can’t find the right product from within our range, then talk to us about our custom design service. We love to experiment and collaborate with our partners to create unique solutions.